See Suhner at IMTS 2014 Booth W-1464! Add them to your show schedule HERE.

Large, long or odd shaped parts present various challenges; self-contained Suhner Multi-Master flex shaft machining units provide solutions

Bulky part machining can often become very difficult to integrate into a manufacturing process, when attempting to perform multiple operations on conventional CNC machines. Limited space or axis travel, one-sided spindle or tool accessibility are common restrictions when trying to design and fit multiple tool requirements onto a rigid machine concept. In addition, cycle time demands and accessibility issues from all sides and angles can make a single tool, 3-axis CNC machine option a losing proposition.

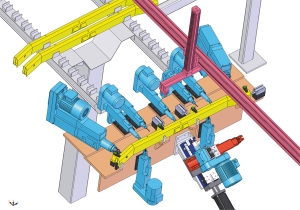

Fig. 1

One new solution involves compact and self-contained single tool Multi-Master flex shaft machining units from SUHNER. These units are modular in design, which means they can be positioned in any direction around a workpiece. In most cases, all operations can be performed in one cycle, thereby reducing the overall machining cycle time to a minimum. Since all tooling modules work simultaneously, the cycle time is basically determined by the longest single machining operation and not the addition of all the tools working together. There are virtually no limitations to part size and the number of tools that are engaged at the same time, with this arrangement.gid machine concept. In addition, cycle time demands and accessibility issues from all sides and angles can make a single tool, 3-axis CNC machine option a losing proposition.

SUHNER offers a complete spindle program with optional feed systems…pneumatic, hydraulic and CNC…available in a quill feed or slide and spindle design. In combination with modern tooling technology, SUHNER Multi-Master machining units can achieve a high degree of performance and accuracy, when incorporated into a machine design.

Solid carbide tools permit cutting speeds up to 300 m/min in aluminum, at feed rates of 0.5 mm/rev. These rates result in very short cycle times and extended tool life.

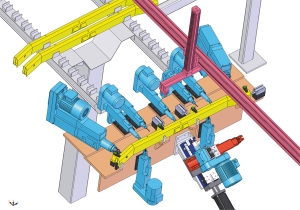

Fig. 2

Pictured transfer machine (Fig.1) illustrates a drilling station for an aluminum profile with 11 drilling operations. The actual machine time is 8 seconds for a roof rack railing. The machine is used in 3 shifts and produces a finished part in less than 20 seconds.

Depending on tool diameter, some of the drilling station units operate at 12,000 rpm.

A special purpose machine is shown in Fig. 2. This machine provides 33 holes in an automotive fiberglass- reinforced plastic part in less than 2.5 seconds. Years of experience and research with special tools and materials result in exeptional hole quality.

For all chipmaking operations including drilling, tapping, milling, reaming, flow drilling, boring, turning, inside and outside grooving etc. with internal or external coolant supply, SUHNER offers a comprehensive machining unit program for machine builders and end users alike.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Need an easy and quick way to transmit rotary motion from a power source –motor or hand wheel – to where you need the movement? Maybe around a corner? Compensating for some offset? Allowing relative movement between the two components? Reaching into that impossible to reach space?

Need an easy and quick way to transmit rotary motion from a power source –motor or hand wheel – to where you need the movement? Maybe around a corner? Compensating for some offset? Allowing relative movement between the two components? Reaching into that impossible to reach space?